introductionThe Best Excel Alternatives for Oil Field Data Management

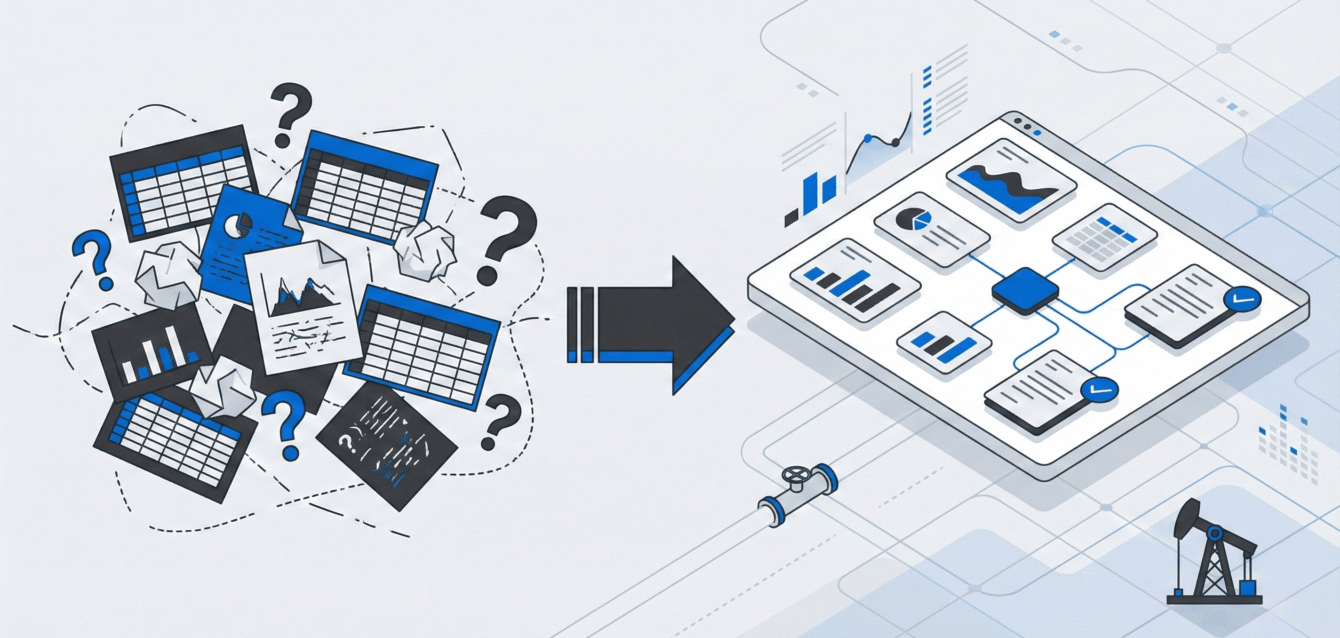

If you have ever spent a morning hunting for the “correct” version of a well database spreadsheet, you already know the problem. Excel is powerful for calculations and quick analysis, but using it as the backbone of your oil field data management creates friction that compounds over time.

The oil and gas industry produces massive volumes of data every day. Production numbers, maintenance records, regulatory filings, and field observations all need to flow between wellsites, field offices, and headquarters. When this data lives in spreadsheets, small inefficiencies become major obstacles.

This guide examines why operators are moving away from Excel-based systems, what features actually matter in oil field software, and how to evaluate alternatives without getting locked into enterprise solutions that cost more than they solve.

Why Excel Falls Short for Oil Field Operations

Excel was designed for individual analysis and financial modeling. It excels at those tasks. But oil field data management requires capabilities that spreadsheets fundamentally lack.

Scalability Breaks Down

As your operations grow, so does the complexity. More wells mean more data points, more stakeholders, and more files. Industry analysts note that spreadsheets “simply weren’t designed to handle this level of complexity.” The more sheets and formulas you add, the more fragile your system becomes.

A single well might generate production data, maintenance logs, regulatory filings, and environmental monitoring records. Multiply that across dozens or hundreds of wells, and spreadsheet management becomes a full-time job.

Version Control Creates Chaos

When five people have five copies of the same file, determining which version is authoritative requires detective work. The problem multiplies when field staff update their local copies and email them back to the office.

One common scenario: a field operator updates production numbers on Tuesday, but the office is working from Monday’s file. Nobody realizes the discrepancy until end-of-month reporting reveals gaps that need manual reconciliation.

Data Silos Block Visibility

Production data in one spreadsheet. Maintenance records in another. Regulatory filings somewhere else entirely. Getting a complete picture of any well means opening multiple files and cross-referencing manually.

Data management experts observe that information often “remains siloed across departments or stored in outdated formats.” Without integration, decision-makers cannot act quickly because they lack confidence in data accuracy.

Manual Processes Invite Errors

Despite automation features, Excel still requires extensive manual data entry. In high-stakes operations, these errors can cascade into increased costs or safety incidents. A misplaced decimal point in production data or a transposed well identifier creates problems that take hours to trace and correct.

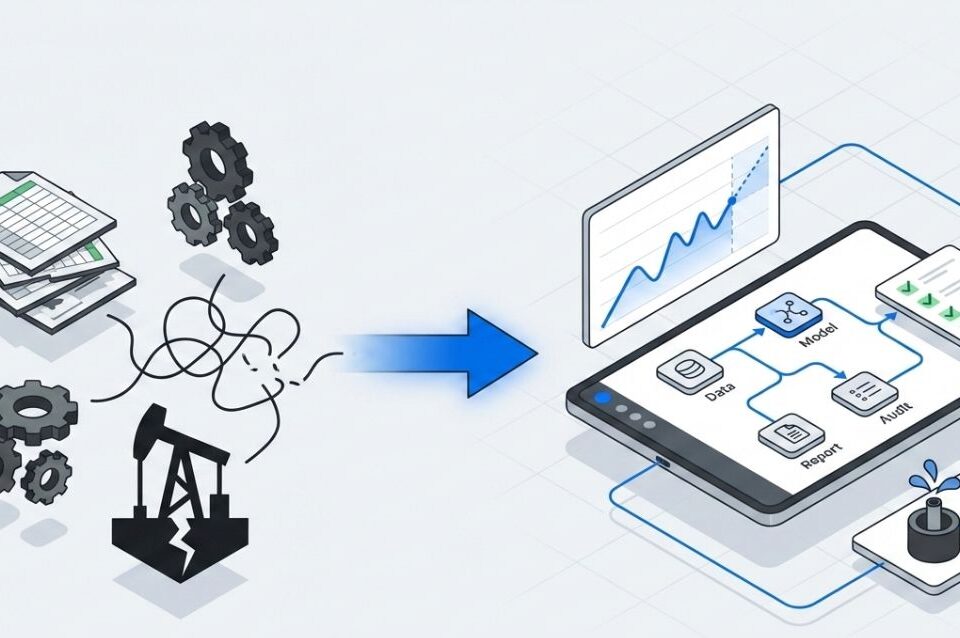

What Oil Field Software Actually Needs to Do

Moving away from spreadsheets only makes sense if the replacement solves real problems. Here are the capabilities that matter most for oil field operations.

Centralized Data Repository

Every piece of data, whether it originates in the field, the office, or from a third party, should feed into a single system. This eliminates version conflicts and ensures everyone works from the same information.

A centralized approach means production data, maintenance records, and regulatory information live together. When you need a complete history for any well, you query one system instead of assembling data from scattered files.

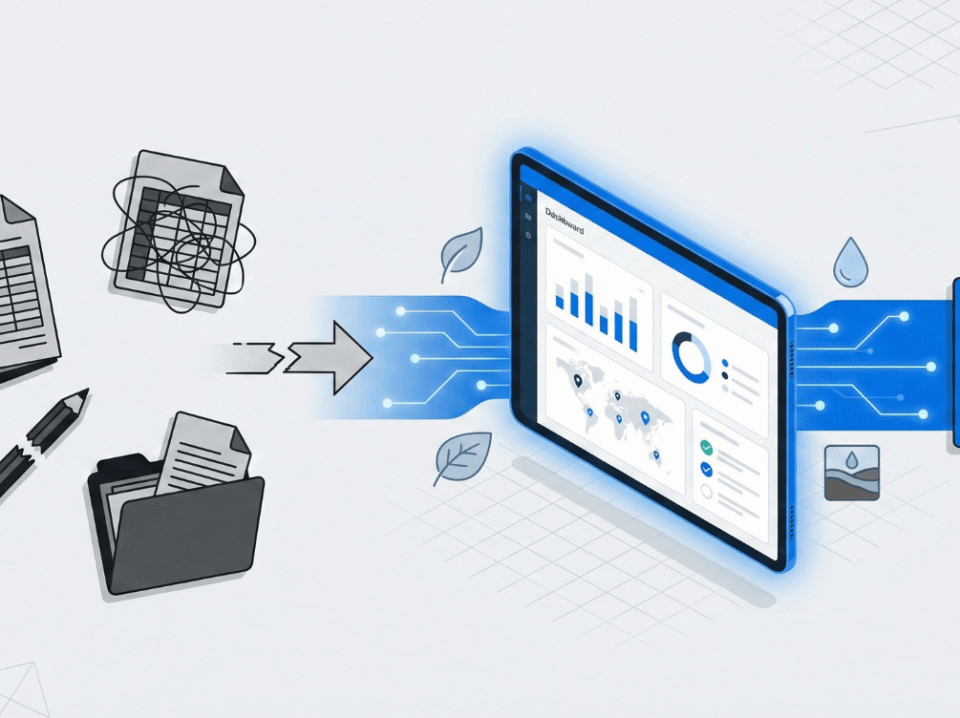

Field-to-Office Data Flow

Field operators capture data at wellsites, often in locations without reliable connectivity. Effective software handles offline data collection and syncs automatically when connection restores.

This capability closes the gap between what happens in the field and what headquarters sees. Instead of waiting for someone to manually enter field notes, data flows through as soon as conditions allow.

Built-In Validation

Spreadsheets accept any input without question. Purpose-built software can enforce validation rules, flag anomalies, and require specific fields before records save. This catches errors at the point of entry rather than during downstream analysis.

Validation might include acceptable ranges for production numbers, required fields for regulatory compliance, or automatic unit conversions to maintain consistency.

Audit Trail and Change History

Regulatory agencies and internal audits require knowing who changed what and when. Spreadsheets offer no native tracking for this. Proper data management systems log every modification with timestamps and user identification.

This capability proves especially valuable during audits or when reconstructing the history of a well for divestiture or acquisition.

Reporting Without Assembly

Generating reports from spreadsheets means hunting through folders, combining files, and formatting results. Integrated software pulls from a single data source, applying consistent formatting and ensuring nothing gets missed.

Regular reports like production summaries, compliance filings, and management dashboards should generate with minimal manual effort.

How to Evaluate Excel Alternatives

Not every oil field software solution fits every operation. The right choice depends on your scale, budget, and specific requirements.

Consider Your Operational Scale

Enterprise solutions like large ERP platforms make sense for major operators managing hundreds of wells across multiple regions. Smaller operators and mid-sized companies often find these systems over-engineered for their needs.

The middle ground between spreadsheets and enterprise software serves many operators better. Purpose-built solutions designed for oil and gas asset management can deliver core functionality without requiring dedicated IT staff or six-figure implementations.

Map Your Integration Needs

Your data management system will need to connect with other tools. Consider your accounting software, regulatory reporting systems, and any specialized applications for reservoir engineering or production optimization.

Look for platforms that support standard data exports and offer integration capabilities with common industry tools.

Evaluate Total Cost of Ownership

Enterprise software carries enterprise price tags, but spreadsheets have hidden costs in labor, errors, and compliance risk. Calculate what you currently spend managing spreadsheet chaos: the hours spent reconciling versions, the rework from data entry errors, and the scramble before regulatory deadlines.

Purpose-built solutions typically offer subscription pricing that scales with your operation. This makes budgeting predictable and avoids large upfront capital expenditure.

Test Field Usability

Software that works perfectly in an office environment may fail in field conditions. Ask about offline capabilities, mobile interfaces, and whether field staff can realistically adopt the system without extensive training.

The best systems accommodate non-technical users with intuitive interfaces while still providing the depth that technical staff need.

Key Features to Prioritize

When evaluating specific platforms, focus on capabilities that address your biggest pain points.

Production Data Management

Track daily production volumes, allocations, and trends across your entire portfolio. Look for systems that can handle the specific calculations and reporting formats required by your regulatory jurisdiction.

Asset Tracking and Maintenance

Every piece of equipment has a lifecycle. Effective software tracks installation dates, maintenance history, and upcoming service requirements. This enables proactive maintenance rather than reactive repairs.

Link maintenance records to specific wells and equipment for complete asset histories. This information proves critical for ARO tracking and forecasting.

Regulatory Compliance Support

Canadian operators face specific requirements from provincial regulators. Software should support the filing formats and schedules required by bodies like the Alberta Energy Regulator or the BC Oil and Gas Commission.

Built-in compliance tracking helps you stay ahead of deadlines rather than scrambling when regulators request information.

Cost and Budget Tracking

Financial management ties directly to operational data. Systems that integrate cost tracking with project and asset tracking provide clearer visibility into operational economics.

This integration supports better budgeting and enables analysis of cost drivers across your portfolio.

Making the Transition

Moving from spreadsheets to proper software does not require a dramatic overhaul. The most successful transitions happen incrementally.

Start With Your Biggest Pain Point

Identify the spreadsheet process that causes the most friction. For many operators, that means production data management or regulatory filing preparation. Begin your transition there and expand to other areas once the initial implementation proves successful.

Plan for Data Migration

Your existing spreadsheet data has value. Good software providers offer data migration support to bring historical records into the new system. This ensures continuity and preserves the information you have already captured.

Train for Adoption

Software only delivers value when people actually use it. Budget time for training and expect an adjustment period. Field staff especially need clear guidance on new workflows and visible benefits to embrace the change.

Measure Improvement

Track metrics before and after implementation. Hours spent on reporting, error rates in production data, time to respond to regulatory requests. These measurements demonstrate return on investment and identify areas for continued optimization.

Common Concerns Addressed

Will this disrupt current operations?

Properly implemented software integrates alongside existing workflows. You do not need to stop operations to start using a new system. Most teams run parallel processes during transition, gradually shifting to the new platform as confidence builds.

What about our existing data?

Historical data can migrate into new systems. The quality of migration depends on how well-organized your current spreadsheets are, but even messy data can be cleaned and imported with proper planning.

What about our existing data?

Most teams notice immediate improvements in data accessibility and version control. Broader benefits like reduced reporting time and better compliance tracking typically become apparent within the first few months of use.

conclusionNext Step

Spreadsheets served the industry for decades, but the complexity of modern oil and gas operations has outgrown what they can reliably manage. The question is not whether to move to purpose-built software, but which solution fits your specific operation.

If your team spends more time managing data than using it, the calculation has already tipped toward change. The operators who make this transition gain time back for actual engineering and operational decisions rather than spreadsheet maintenance.

Ready to see how purpose-built software handles oil field data management?

Request a demo to explore how Fieldshare can replace your spreadsheet chaos with organized, accessible, and reliable data management.